Introduction

Industrial robotics has revolutionized the manufacturing industry by automating various tasks and processes. These intelligent machines offer increased efficiency, productivity, and precision, transforming the way goods are produced. The industrial robotics market has witnessed significant growth in recent years, driven by advancements in technology, rising demand for automation, and the need to enhance operational efficiency. This article explores the key aspects of the industrial robotics market, including its current landscape, growth drivers, challenges, and future prospects.

Table of Contents

- Overview of Industrial Robotics

- Types of Industrial Robots

- Articulated Robots

- Cartesian Robots

- SCARA Robots

- Collaborative Robots

- Applications of Industrial Robotics

- Automotive Industry

- Electronics Industry

- Food and Beverage Industry

- Healthcare Industry

- Advantages of Industrial Robotics

- Increased Productivity

- Improved Quality and Precision

- Enhanced Safety

- Cost Reduction

- Key Market Trends

- Integration of Artificial Intelligence and Machine Learning

- Growing Adoption of Collaborative Robots

- Expansion of Industrial Robotics in Emerging Economies

- Adoption of Industrial Robots in Small and Medium-sized Enterprises (SMEs)

- Market Challenges

- High Initial Investment

- Complex Integration Process

- Workforce Concerns

- Security and Cyber Threats

- Future Outlook

- Advancements in Robotic Technologies

- Industry 4.0 and Industrial Robotics

- Collaborative Robotics in the Healthcare Sector

- Growing Demand for Service Robots

- Conclusion

- Frequently Asked Questions (FAQs)

1. Overview of Industrial Robotics

Industrial robotics involves the use of automated machines to perform tasks that were traditionally carried out by humans. These robots are designed to operate in manufacturing plants, assembly lines, and warehouses, among other industrial settings. They are equipped with advanced sensors, software, and mechanical components to carry out a wide range of functions efficiently.

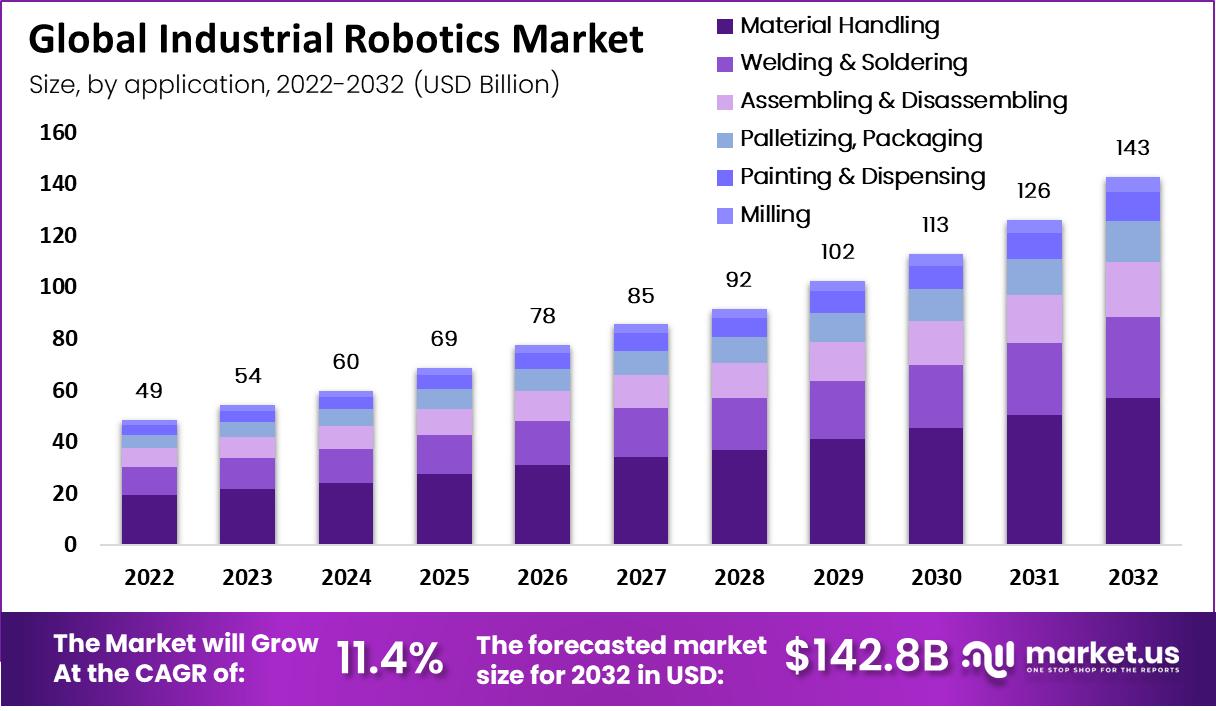

According to Market.us, The global industrial robotics market was valued at around USD 48.5 billion in 2022 and is expected to reach approximately USD 142.8 billion in 2032, growing at a CAGR of slightly above 11.4% between 2023 and 2032.

2. Types of Industrial Robots

2.1 Articulated Robots

Articulated robots are the most common type of industrial robots. They consist of multiple rotary joints, allowing them to move with a high degree of freedom. These robots excel in applications that require flexibility and agility, such as welding, painting, and material handling.

2.2 Cartesian Robots

Cartesian robots, also known as gantry robots, operate on three linear axes (X, Y, and Z). They are widely used for pick and place operations, packaging, and assembly tasks. Cartesian robots offer high precision and are ideal for applications that require repetitive movements within a fixed workspace.

2.3 SCARA Robots

SCARA (Selective Compliance Assembly Robot Arm) robots are known for their fast and precise vertical movements. They are commonly used in assembly and material handling processes. SCARA robots are best suited for tasks that involve a combination of horizontal and vertical motions.

2.4 Collaborative Robots

Collaborative robots, or cobots, are designed to work alongside humans in a shared workspace. These robots feature advanced safety features and are programmed to assist workers in various tasks, enhancing productivity and safety. Collaborative robots are gaining popularity in industries such as electronics, healthcare, and automotive.

3. Applications of Industrial Robotics

Industrial robotics finds applications across various industries. Here are some notable examples:

3.1 Automotive Industry

The automotive industry extensively utilizes industrial robots for tasks like welding, painting, and assembly. Robots enable high precision and speed in manufacturing processes, leading to improved quality and productivity.

3.2 Electronics Industry

In the electronics industry, robots are used for handling delicate components, circuit board assembly, and quality inspection. The precise movements of robots ensure accuracy and reduce the risk of human error.

3.3 Food and Beverage Industry

Industrial robots play a crucial role in food processing and packaging. They can perform tasks such as sorting, cutting, and packaging, ensuring consistent quality and hygiene standards.

3.4 Healthcare Industry

The healthcare sector is increasingly adopting robotics to assist in various tasks, including surgery, rehabilitation, and patient care. Robotic systems offer precise control and enable minimally invasive procedures, improving patient outcomes.

4. Advantages of Industrial Robotics

The adoption of industrial robotics provides several benefits to organizations. Here are some key advantages:

4.1 Increased Productivity

Industrial robots can work tirelessly without fatigue, leading to higher production rates and reduced cycle times. They can operate 24/7, resulting in increased overall productivity.

4.2 Improved Quality and Precision

Robots perform tasks with exceptional accuracy, minimizing errors and ensuring consistent quality. This leads to improved product quality and customer satisfaction.

4.3 Enhanced Safety

By automating hazardous or repetitive tasks, industrial robots reduce the risk of workplace accidents and injuries. They can handle tasks in dangerous environments or handle toxic substances, protecting human workers.

4.4 Cost Reduction

Although the initial investment in industrial robotics may be significant, it often results in long-term cost savings. Robots can perform tasks faster and more efficiently, reducing labor costs and minimizing material waste.

Suggested Reading: Unleashing the Power of Industrial Robotics: Exploring the Thriving Market and Future Opportunities

5. Key Market Trends

The industrial robotics market is subject to various trends that shape its growth and development. Here are some significant trends:

5.1 Integration of Artificial Intelligence and Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) technologies with industrial robots is transforming the industry. AI-powered robots can learn from data, adapt to changing conditions, and make intelligent decisions, further enhancing their capabilities.

5.2 Growing Adoption of Collaborative Robots

Collaborative robots are becoming increasingly popular due to their ability to work safely alongside humans. These robots can assist workers in tasks that require precision, strength, or repetitive movements, contributing to improved productivity and job satisfaction.

5.3 Expansion of Industrial Robotics in Emerging Economies

Emerging economies are witnessing a surge in industrial robotics adoption. Factors such as rapid industrialization, increasing labor costs, and a focus on improving productivity are driving the growth of the industrial robotics market in these regions.

5.4 Adoption of Industrial Robots in Small and Medium-sized Enterprises (SMEs)

Previously dominated by large corporations, the industrial robotics market is now witnessing increased adoption by small and medium-sized enterprises (SMEs). The availability of cost-effective and user-friendly robotic solutions has made automation accessible to a wider range of businesses.

6. Market Challenges

While the industrial robotics market offers significant opportunities, it also faces several challenges. These challenges include:

6.1 High Initial Investment

The initial cost of implementing industrial robotics can be substantial, making it a barrier for some organizations, particularly SMEs. However, the long-term benefits and cost savings often justify the investment.

6.2 Complex Integration Process

Integrating robots into existing workflows and systems can be a complex process. It requires careful planning, coordination, and training to ensure smooth integrationand optimize the robot’s performance.

6.3 Workforce Concerns

The introduction of industrial robots in the workplace can raise concerns among workers regarding job security. It is essential for organizations to communicate transparently and provide retraining opportunities to ensure a smooth transition and maintain a harmonious work environment.

6.4 Security and Cyber Threats

As industrial robots become more connected and integrated with other systems, the risk of cybersecurity threats increases. Protecting robots from potential hacking or malicious attacks is crucial to maintain the integrity and safety of industrial operations.

7. Future Outlook

The future of the industrial robotics market is promising, with several exciting developments on the horizon. Here are some areas to watch:

7.1 Advancements in Robotic Technologies

Continuous advancements in robotic technologies, such as sensor capabilities, machine vision, and mobility, will enhance the capabilities of industrial robots. This will lead to more sophisticated and versatile robots capable of handling complex tasks.

7.2 Industry 4.0 and Industrial Robotics

The integration of industrial robotics with Industry 4.0 concepts, such as the Internet of Things (IoT) and data analytics, will further optimize manufacturing processes. This integration will enable real-time monitoring, predictive maintenance, and adaptive manufacturing, resulting in increased efficiency and flexibility.

7.3 Collaborative Robotics in the Healthcare Sector

The healthcare industry is expected to witness significant growth in the adoption of collaborative robots. These robots can assist healthcare professionals in tasks such as surgery, patient care, and rehabilitation, leading to improved patient outcomes and increased efficiency in healthcare delivery.

7.4 Growing Demand for Service Robots

Beyond the manufacturing sector, there is a growing demand for service robots in areas like hospitality, retail, and logistics. Service robots can perform tasks such as customer service, delivery, and inventory management, augmenting human capabilities and streamlining operations.

8. Conclusion

The industrial robotics market continues to expand as organizations seek automation solutions to improve productivity, quality, and safety. With advancements in technology, the integration of AI and ML, and the rise of collaborative robots, the future of industrial robotics looks promising. However, challenges such as high initial costs and integration complexities must be addressed. As the market evolves, industrial robotics will play a vital role in transforming industries and driving innovation.

Frequently Asked Questions (FAQs)

1. What is industrial robotics?

Industrial robotics refers to the use of automated machines to perform tasks in industrial settings. These robots are equipped with advanced sensors, software, and mechanical components to carry out various functions efficiently.

2. What are the types of industrial robots?

There are different types of industrial robots, including articulated robots, Cartesian robots, SCARA robots, and collaborative robots.

3. What are the advantages of industrial robotics?

Industrial robotics offers advantages such as increased productivity, improved quality and precision, enhanced safety, and cost reduction.

4. What are the key market trends in industrial robotics?

Key market trends include the integration of AI and ML, the growing adoption of collaborative robots, expansion in emerging economies, and increased adoption by SMEs.

5. What are the challenges faced by the industrial robotics market?

Challenges include high initial investment, complex integration process, workforce concerns, and security and cyber threats.